Case Study: Our phased 56,000 m³/day UF-RO solution solved Batam’s 40,000 m³/day water deficit, enabling strategic growth for electronics manufacturing and municipal supply. Learn about cost-effective water security.

Case Study: A Phased Water Masterplan for Batam Island’s Economic Future

Focus Keywords: phased water treatment plant, scalable desalination masterplan, Batam Island water solution, dual-purpose RO plant

Executive Summary: Solving Today’s Deficit with Tomorrow’s Vision

Facing a critical 40,000 m³/day water deficit, Batam Island needed a solution that matched its economic ambition. Our response was not just a plant, but a phased water security masterplan—a 56,000 m³/day UF-RO system built in stages to align investment with growth, avoiding $20M in overspending while serving both high-tech industry and community needs.

The Challenge: Strategic Growth Hampered by Water Scarcity

Batam’s rapid ascent as a regional economic and industrial hub was threatened by a fundamental constraint: water. The existing supply could not keep pace, creating a crippling deficit. The challenge was twofold:

Solve the Immediate Crisis: Bridge the 40,000 m³/day gap reliably and quickly.

Plan for a Dynamic Future: Create a flexible, scalable system that would grow with the island’s economy, avoiding the massive capital risk of building over-capacity upfront.

Our Solution: A Phased and Multi-Purpose UF-RO Plant

We designed and deployed a 56,000 m³/day seawater desalination plant as a long-term masterplan, not a one-off project. The solution was built around two core innovations:

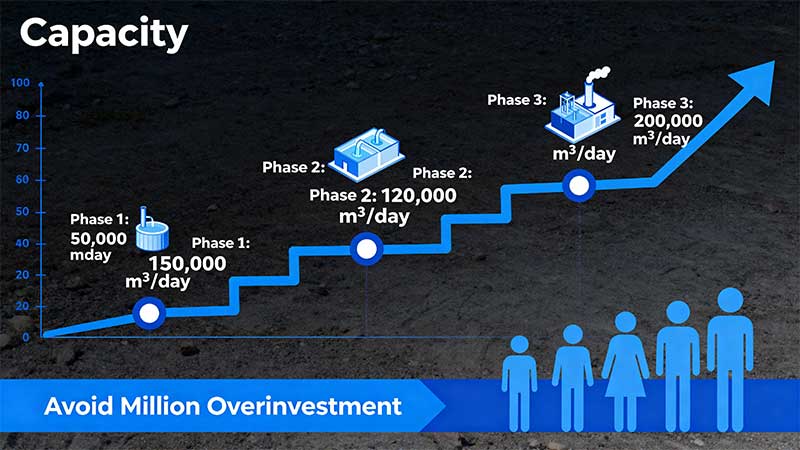

1. The Phased Investment Strategy

The plant was constructed in three deliberate phases (32,000 + 13,000 + 11,000 m³/day). This approach provided:

Capital Efficiency: Capital expenditure was perfectly aligned with actual demand growth.

Risk Mitigation: Eliminated the financial burden and waste of building unused capacity.

Operational Agility: New capacity could be brought online precisely when needed.

2. One Integrated System, Multiple Water Standards

A key engineering achievement was designing a single plant capable of delivering different water purity levels from a central facility:

High-Purity Water: For sensitive industries like electronics manufacturing.

Standard Potable Water: For the municipal supply and community well-being.

The Delivered Value: Economic Foresight Realized

The phased masterplan transformed water from a bottleneck into a catalyst for sustainable prosperity, delivering tangible outcomes:

💰 Right-Sized Investment: Avoided $20M in potential over-capacity costs by building only what was needed, when it was needed.

🏭️ Dual-Purpose Economic Engine: The plant directly supports high-tech industrygrowth, making Batam a more attractive investment destination, while simultaneously securing the community water supply.

🤖 Operational Resilience & Efficiency: Advanced automated controls ensure consistent performance and water quality despite variations in seawater conditions, reducing operational complexity and costs.

Conclusion: Building Smarter for Sustainable Growth

The Batam Island project proves that solving water scarcity isn’t just about scale; it’s about intelligence and strategy. By implementing a phased and multi-purpose masterplan, we provided a resilient, scalable, and cost-effective water security foundation that will support the island’s economy for decades to come.

[Strong, Strategic Call-to-Action]

Ready to Build a Water Strategy That Grows With Your Ambitions?

Whether for a growing city or an industrial hub, our expertise lies in designing phased, scalable water solutions that align investment with real-world demand.

[Contact Our Strategy Experts Today] for a consultation.